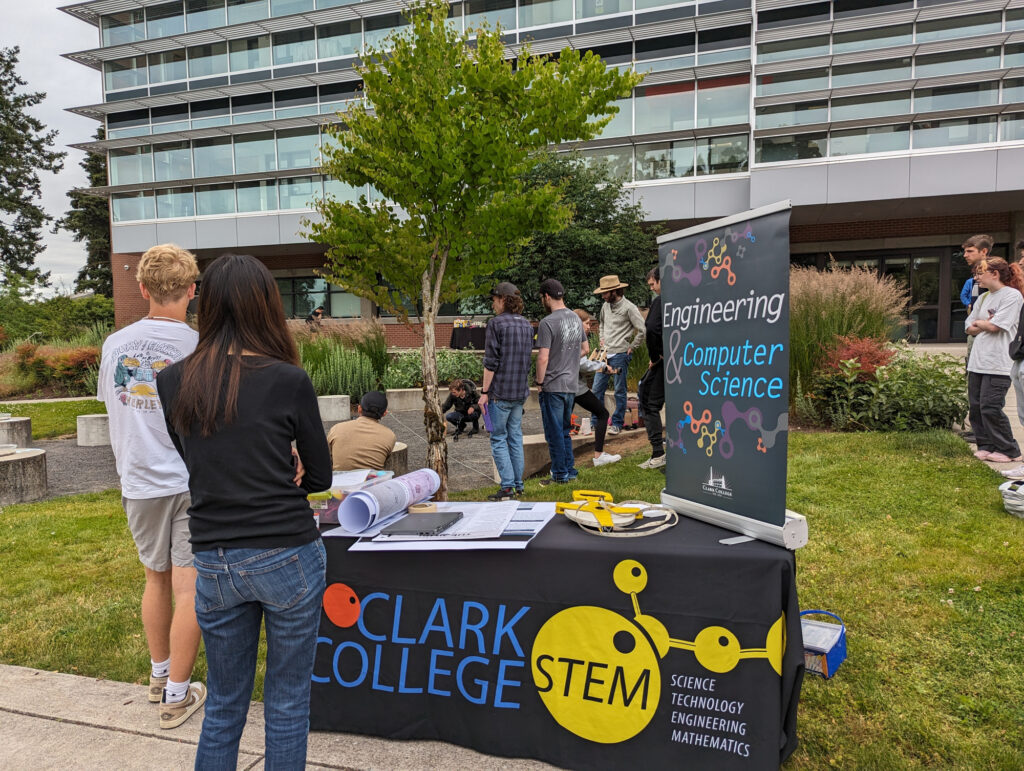

Engineering Competition

Teams of engineering students stood outside the STEM Building engrossed in testing the transforming catapults they had designed and built. How many foam balls would their catapult successfully throw into the target buckets? Could their catapult quickly transform from stationary to mobile, and would it be fast enough to cross the finish line before the clock ran out?

Every term, Engineering professors Tina Barsotti and Carol Hsu pose a real-world problem to their students and instruct them to design and build an object that solves the problem. Teams of students work together. At the end of each term, teams present their prototype to their peers, explaining their process and materials used. Finally, teams test their designs.

The spring 2024 challenge: Design and build a transforming catapult with two stages: stationary and moveable.

Requirements:

- The catapult must pass under a twelve-inch bridge and shoot foam balls into target buckets placed at various distances.

- The catapult must remain stationary while shooting.

- It must transform into a moveable form before and after shooting the balls.

- A student may not push the catapult across the finish line.

Timed test: Five minutes maximum was allowed for their mobile design to move from the starting line to the testing center, to transform to a stationary catapult, then to propel foam balls at the target, to transform back into moveable form, and finally to cross the finish line.

Materials: Student teams used various materials to build their catapult. Popular choices included radio control cars, lightweight wood, balsa craft sticks, cardboard, plastic cups, springs, string, rubber bands, and wheels and axles from a toy car. Some teams used high-tech carbon fiber, PET-CF, and TPU 3D printing filament to create parts of their catapult vehicle. Although all catapults shared some characteristics, such as wheels, a base, a long arm, and a bucket, each catapult looked different from the others.

Most teams were outside the STEM Building awaiting their turn to test their project. But not all teams had completed building their design. Team Proto A and a few other teams who were finishing their catapults worked at tables in the collaboratorium. Students wielded drills, glue guns, duct tape, and string to put the finishing touches on their designs before taking them outside to test them in front of their professors and their peers.

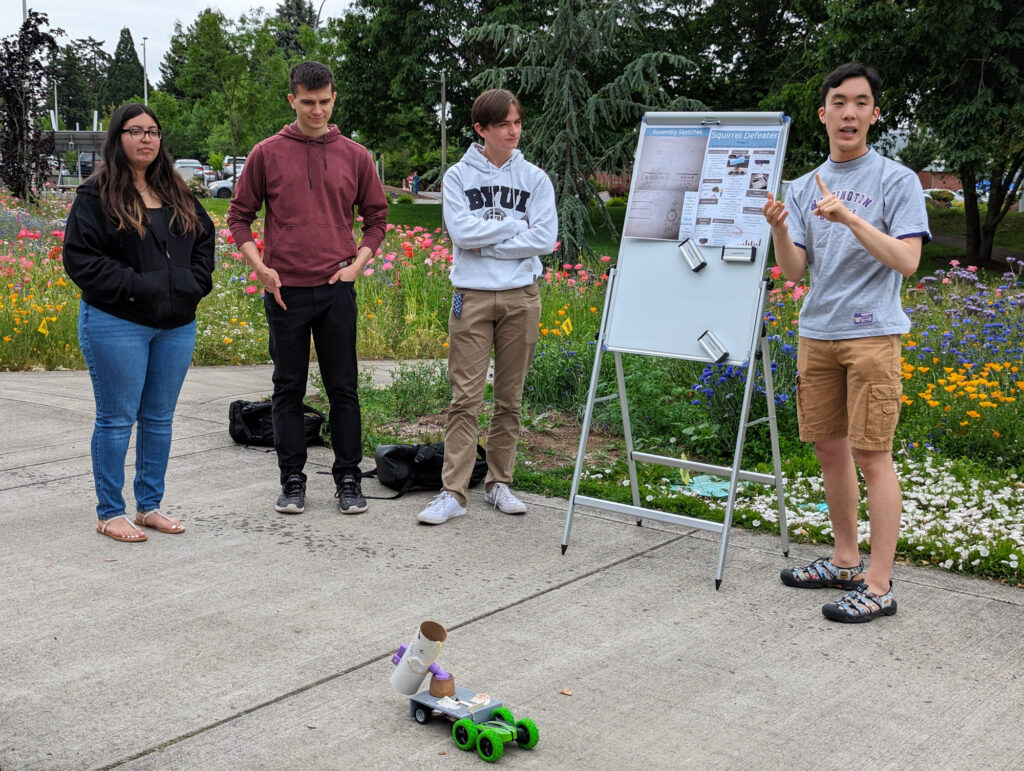

Each team took a turn running their catapult transformer through the course while other teams watched, cheered, and offered encouragement. Now was the moment of truth for Team Proto T and its “Squirrel Defeater” transforming catapult. It completed the tasks and crossed the finish line with 12 seconds to spare.

Photos: Clark College/Susan Parrish