The Bloom Bot Challenge

When planting seeds in a garden, it’s important to distribute them evenly, giving each one space to grow and access the water, sunlight, and nutrients it needs to thrive. That’s the goal every season for our Bee Campus volunteers as they care for the garden just outside the STEM building. But this spring, the challenge of precise seed distribution caught the eye of a different group on campus – the Engineering department. From their windows overlooking the garden, an idea took root: what if students could build a robot to solve this real-world problem?

Spring 2025’s Challenge

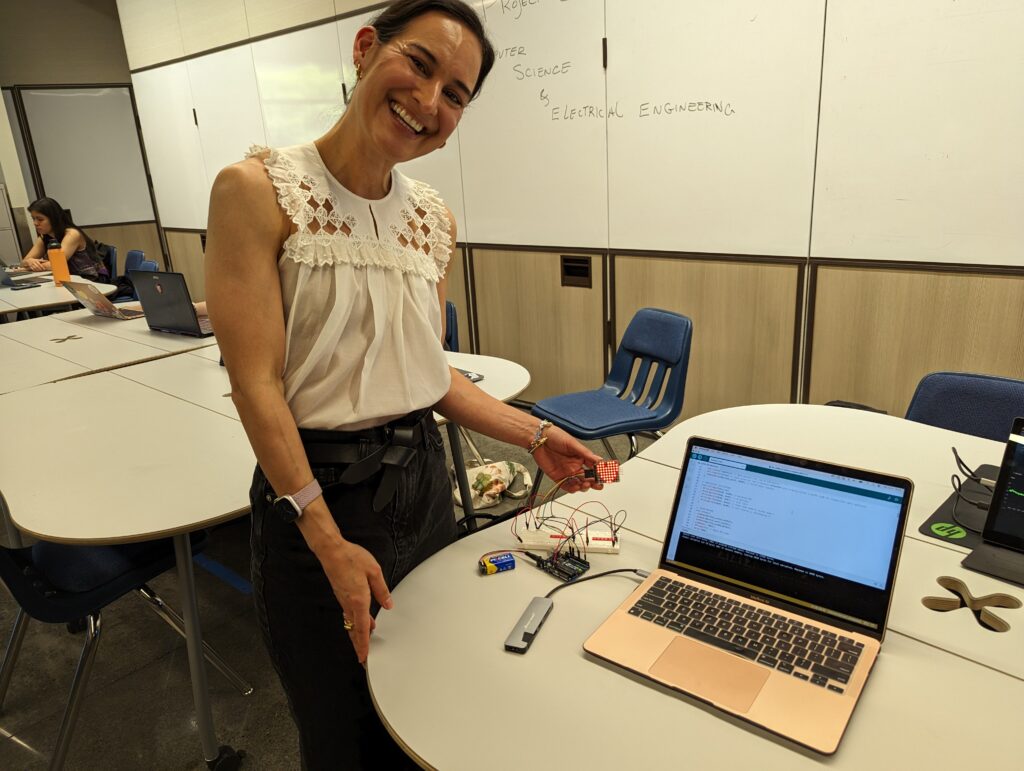

That question inspired the theme for this term’s Engineering Design Competition, “Mission Bloom Bot,” where student teams were tasked with building an autonomous robot that could safely travel along a rope and drop two golf balls – each representing a seed – onto separate targets, all without any human interaction.

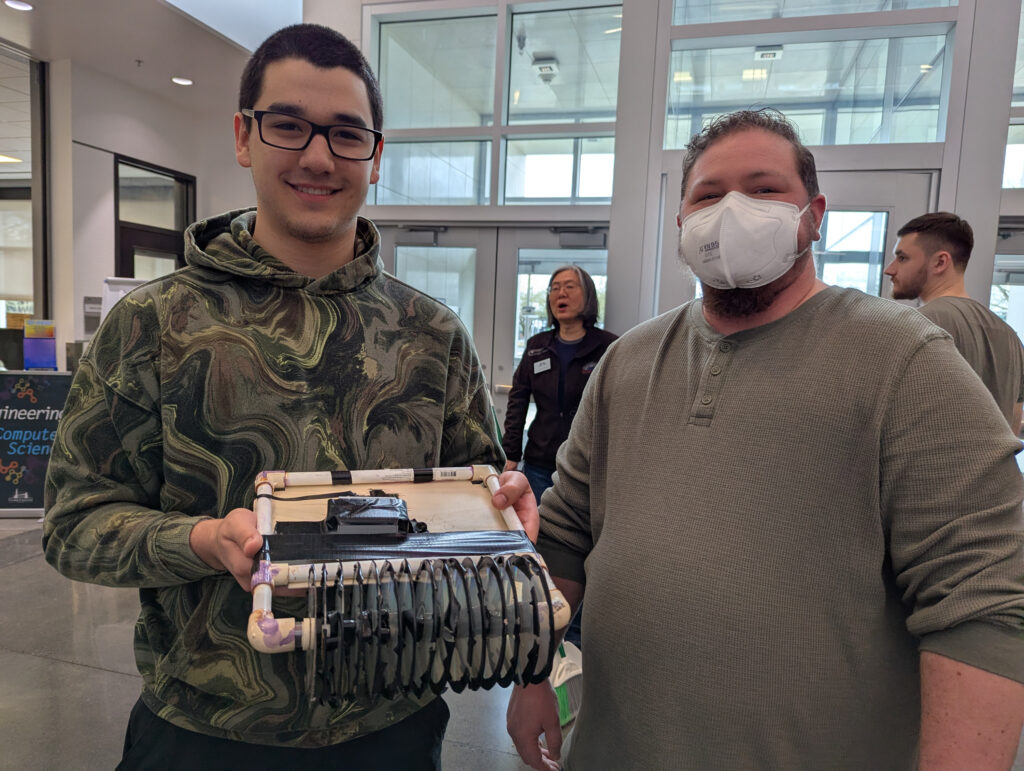

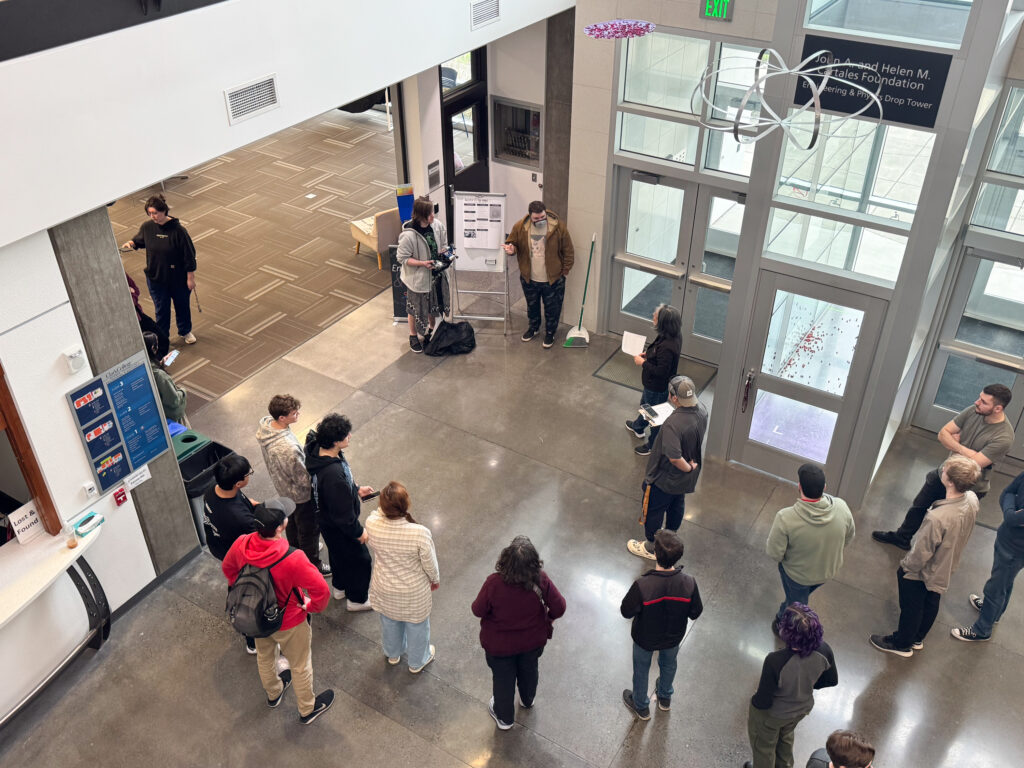

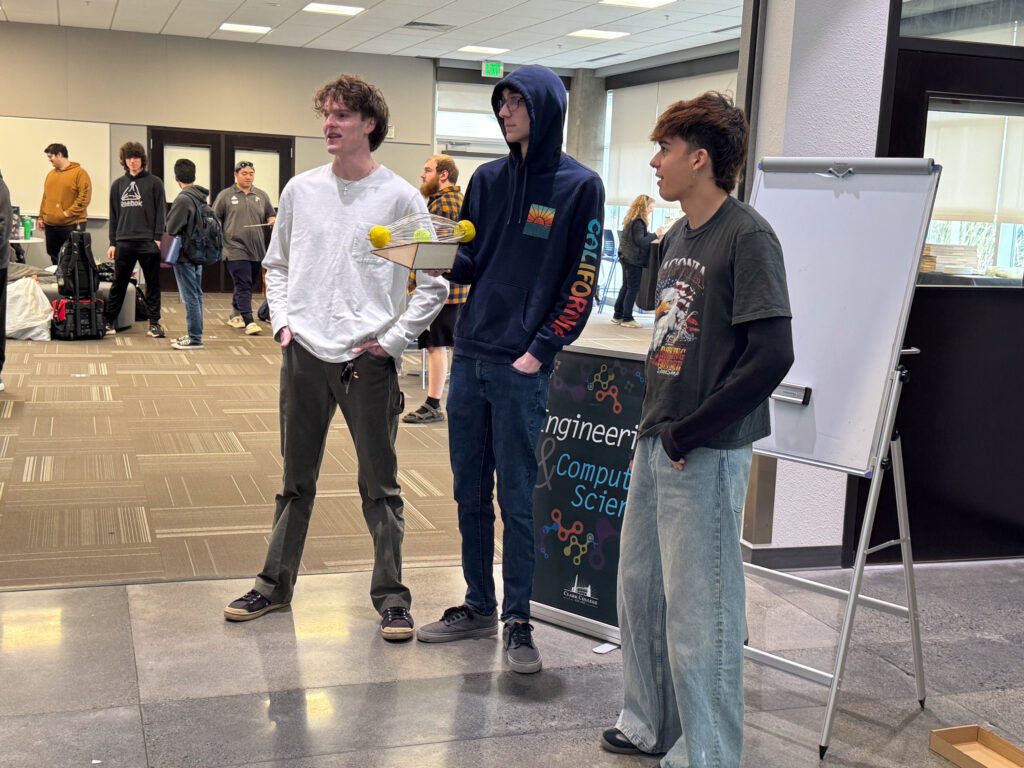

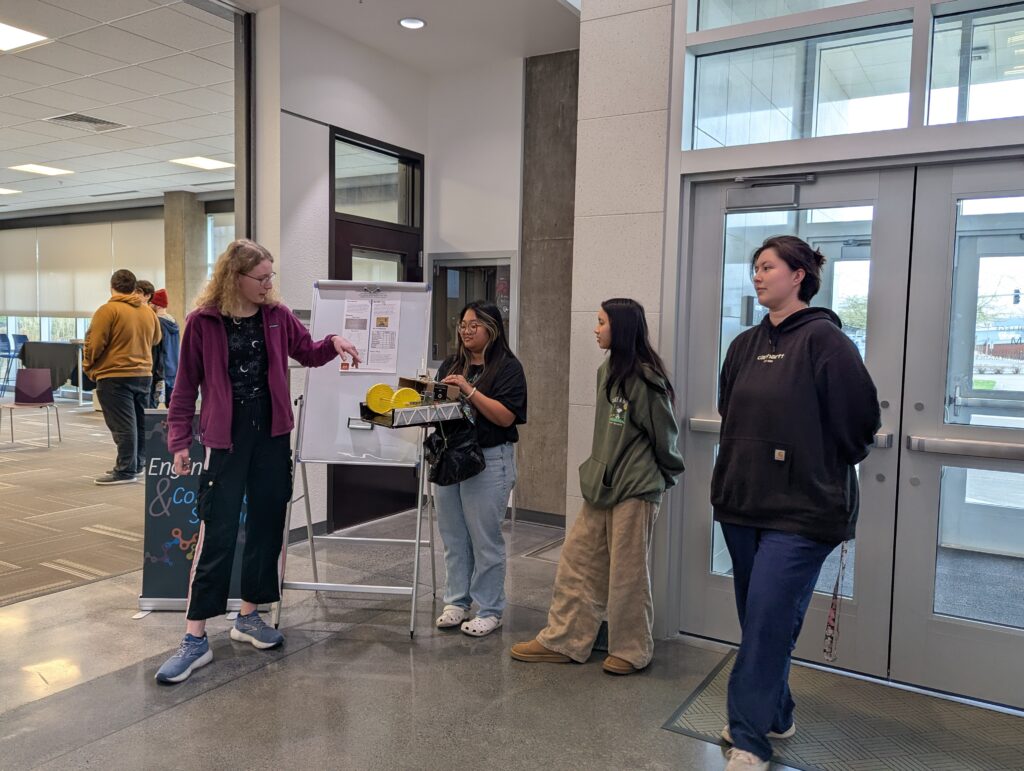

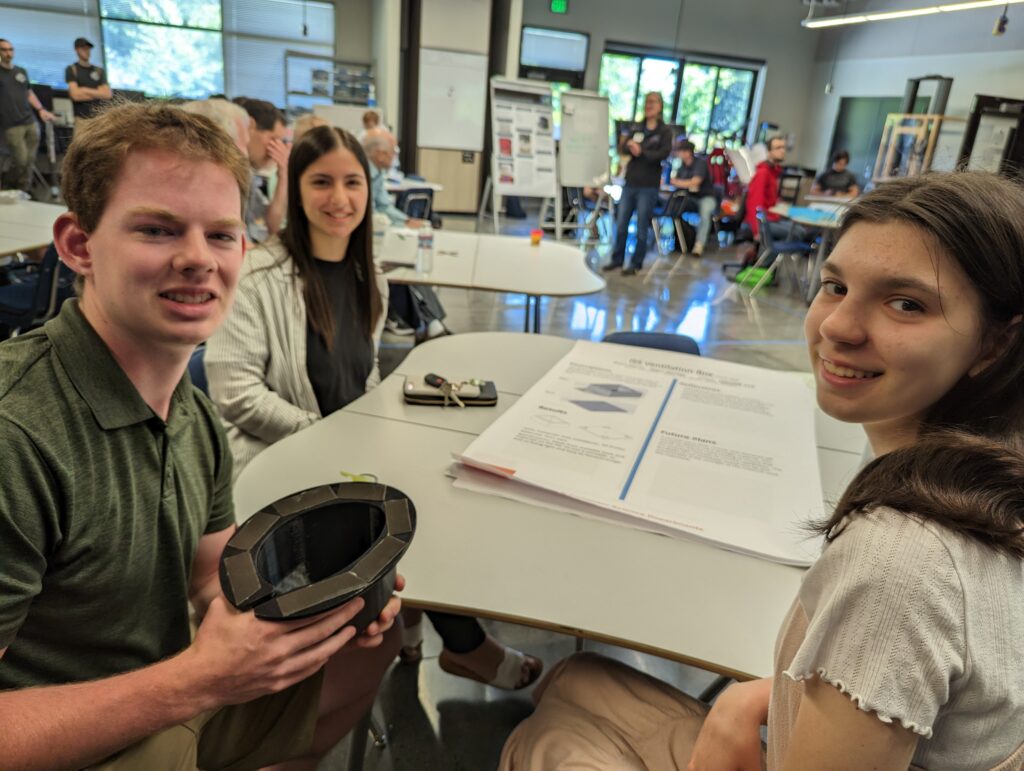

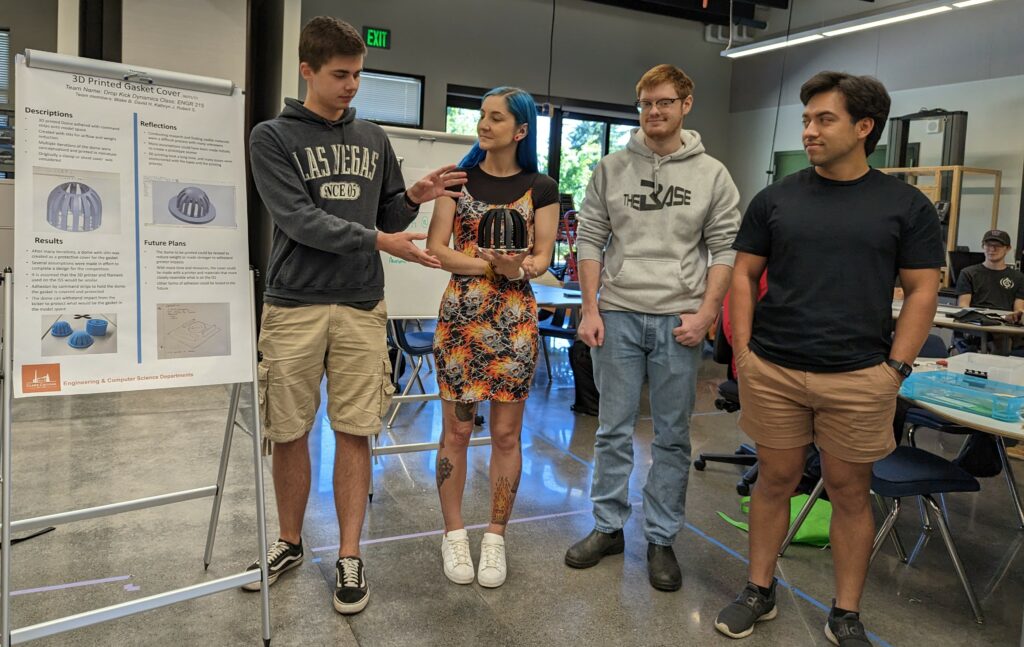

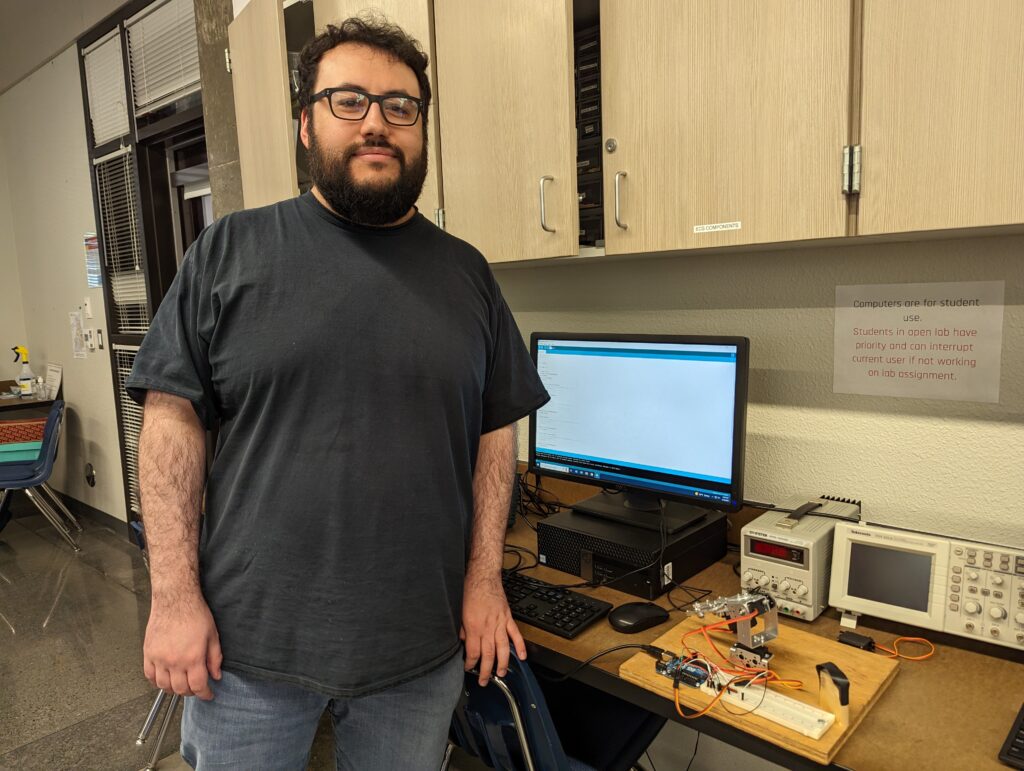

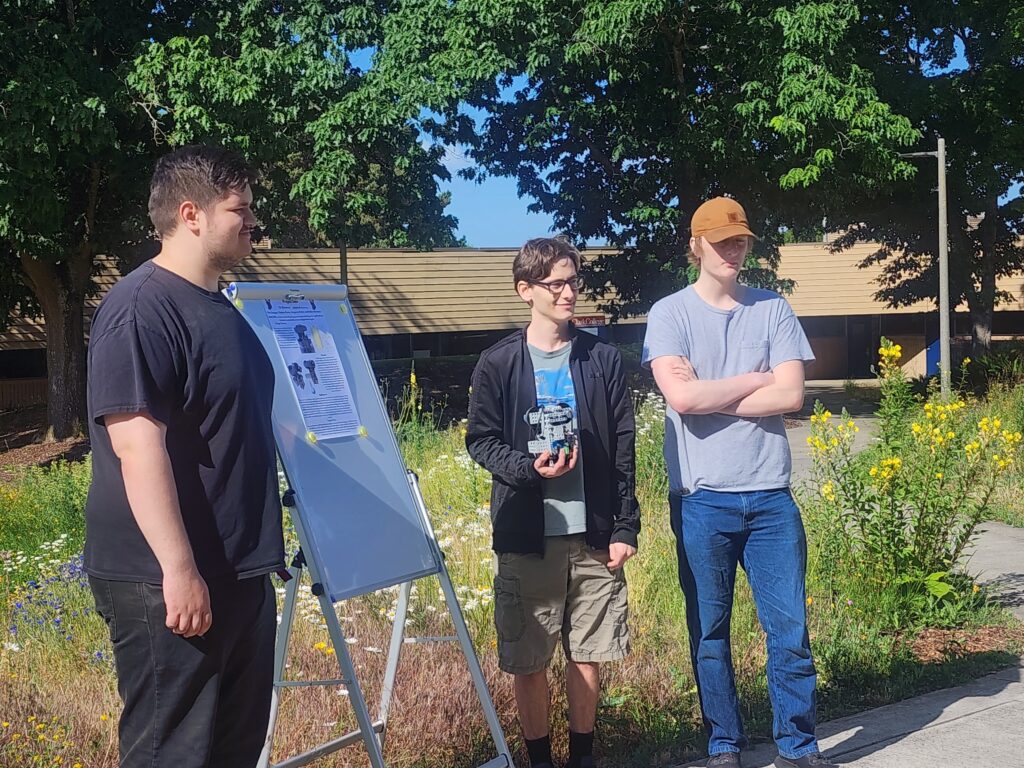

At the event, the teams presented their creations, sharing their design process, materials, mechanisms, potential weaknesses, and uses beyond the scope of the challenge. Then came the moment of truth: each team had five minutes to launch their bot and complete the rope run tied between two trees, with multiple attempts allowed if needed.

From Bee Gardens to Local Agriculture

While the challenge originated with the campus gardens in mind, many teams imagined broader applications in agriculture.

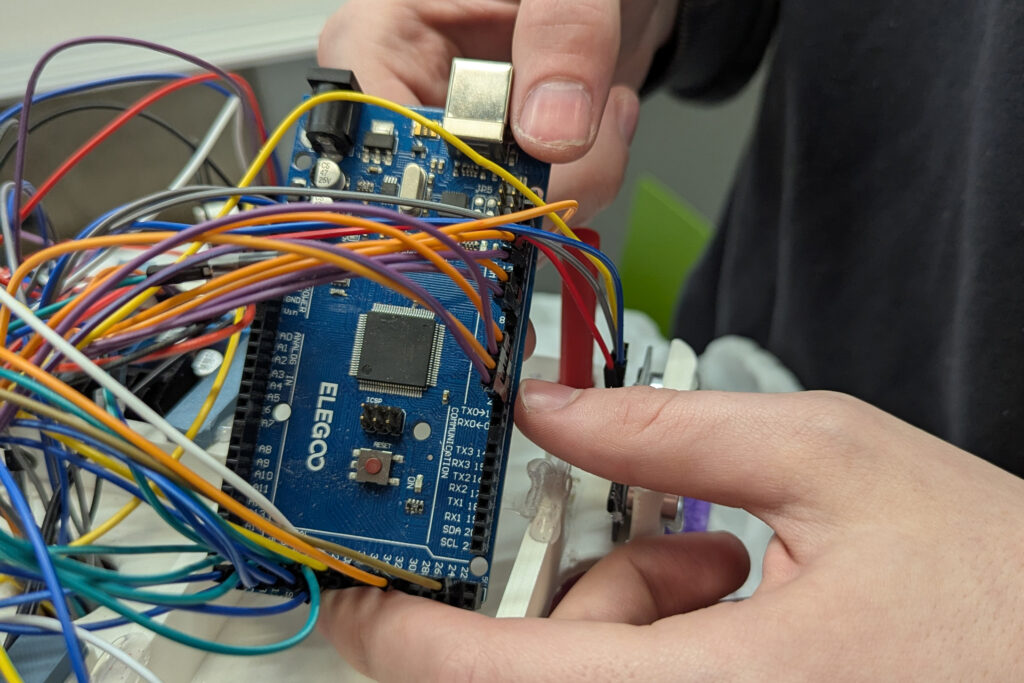

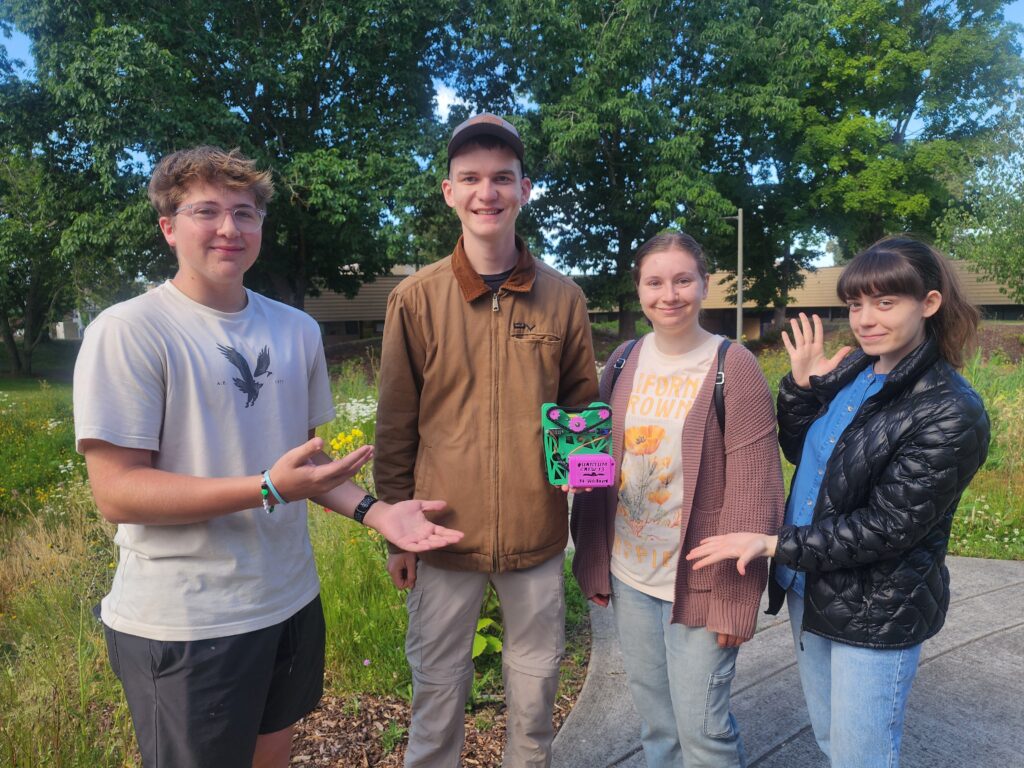

One team introduced their robot, the Quantamelon 2.0 Seed Dropper, a product they designed with farmers in mind. With the exception of the electronics, every component of their robot was 3D printed, resulting in a lightweight and durable build.

“We tried to keep the parameters of the competition in mind, including budget so that it’s easy to produce a lot of them,” said Philip, one of the team members. “3D printing makes it quicker to manufacture and cheaper to produce.”

The Quantamelon 2.0 Seed Dropper features a 12-volt battery and pulley system to pull the robot across the rope. A two-sided arm allowed it to drop the golf balls one at a time, releasing the second one after a set delay. The bot took only 35 seconds to complete its mission. But it wasn’t just functional; it was also fun to watch, decked out in colorful, friendly tones selected by team member Destiny.

Not every bot completed the challenge as planned. Some soared – dropping their golf balls precisely onto the targets, even hitting bullseye – while others struggled with mechanical issues or the unusually hot weather that week, which caused some components to warp or melt. Regardless of any challenges they faced, each team took their turn showcasing their hard work and problem-solving skills.

More about Clark’s Engineering Programs

Clark College offers an Associate of Science Transfer – AST2. It provides the foundation for a four-year Bachelor of Science engineering degree program with a focus in mathematics, chemistry, physics, and engineering. Students can pursue Major Ready Pathway (MRP’s) associate degrees in:

- Bioengineering and Chemical Engineering

- Computer and Electrical Engineering

- Mechanical, Civil, and Aeronautical Engineering

- Computer Science and Engineering

Photos: Clark College/Malena Goerl