Spotlight on Mechatronics

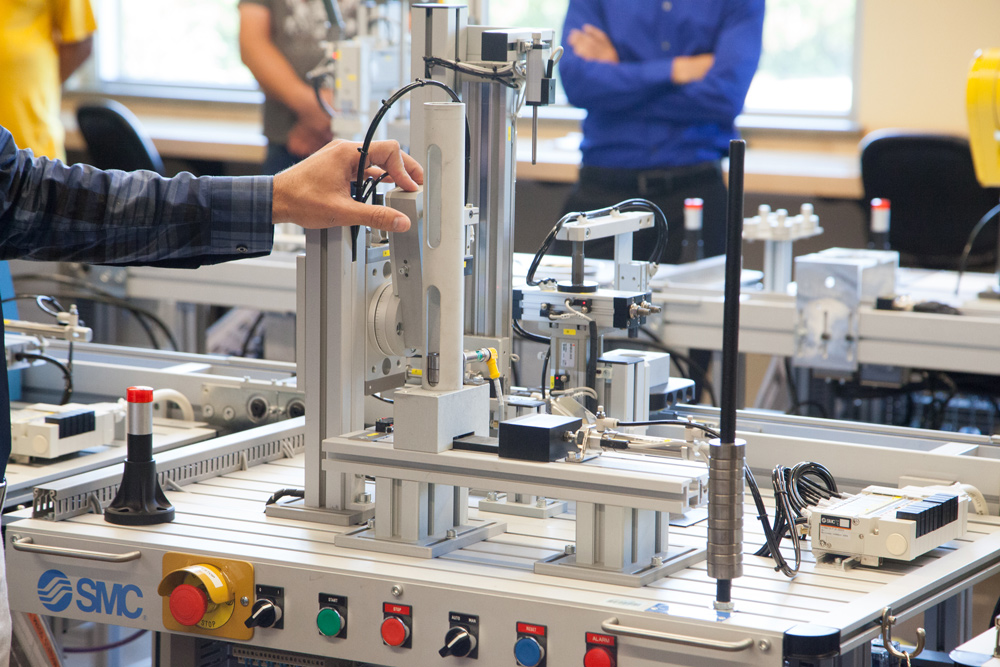

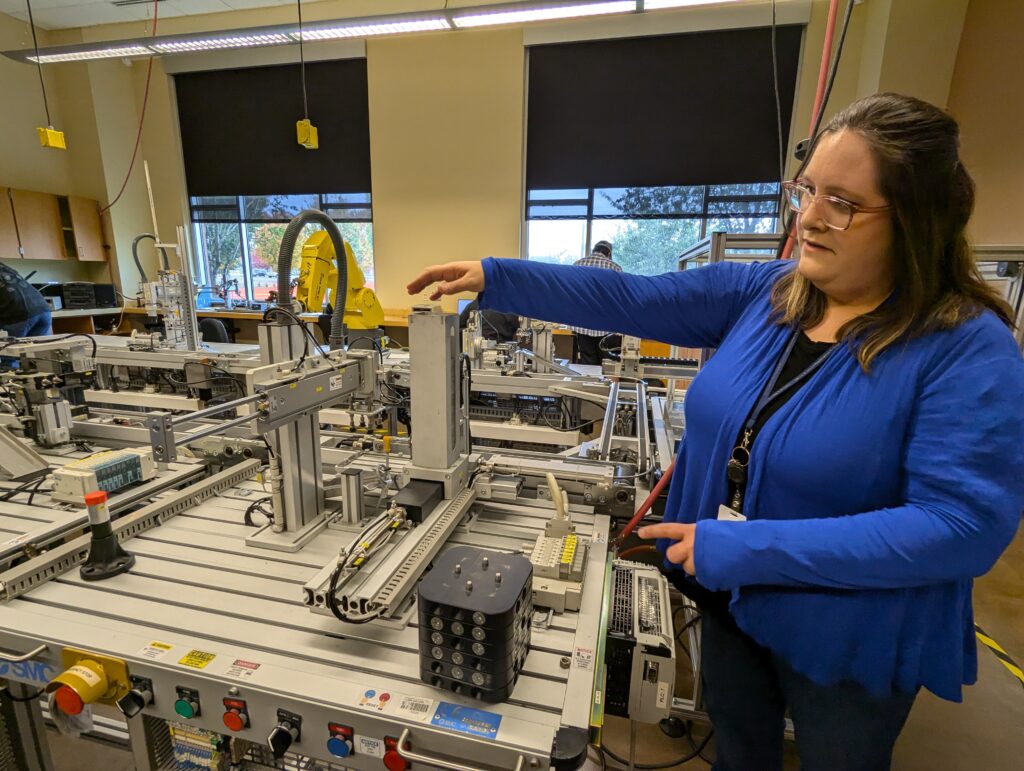

Leading up to the mechatronics open house on October 30, the mechatronics labs at Clark College at Columbia Tech Center are busy with students engaged in hands-on learning—working with a variety of machine systems.

Learn more about this in-demand field that’s a good fit for people who love working with their hands, solving problems, and doing something different every day.

What is mechatronics?

Mechatronics is a growing technical field that integrates mechanical and electronic components managed by control systems. Mechatronics technicians troubleshoot, maintain, and repair mechanical equipment controlled by electrical, electronic, and computer systems. The systems are used in a wide variety of manufacturing and related technical applications, especially in high-tech industries.

Classes emphasize current concepts and technology by providing practical, hands-on experiences with the latest, industry-standard equipment. Coursework includes process control, instrumentation/automation, conveyor, palletizer, and robotics systems.

Instructor Alex Looney said mechatronics students learn valuable skills: analyzing and troubleshooting systems, and learning to safely work with higher voltages.

What can you do with a mechatronics degree?

Tina Jenkins, who heads the mechatronics program, said, “These skills are so versatile that they are used in many industries.”

Mechatronics graduates are equipped to work in manufacturing industries including semiconductor, fabrication, aerospace, and more. Clark’s graduates work at companies including Intel, Amazon, Columbia Machine, SEH America, nLight, Kyocera, TSMC (formerly Wafertech), Analog Devices, Inc. (ADI), and Georgia Pacific. The program’s faculty has built relationships with several local employers to ensure that the program stays current.

Who is a good fit for mechatronics?

Jenkins listed traits that are essential for this work: investigating, troubleshooting, and being curious about electronics and mechanical systems.

Instructor Ben Saunders said, “Mechatronics covers a broad range and is geared for people who want to be technicians, but perhaps not engineers. The classes are definitely hands-on.”

Instructor Alex Looney said, “If you see electronic equipment and wonder how it works, you’d be a good fit for mechatronics.”

CHIPS and Science Act: Why mechatronics jobs are in demand

High-tech manufacturing jobs—including mechatronics—are on the rise, thanks in large part to the $280 billion CHIPS and Science Act (CHIPS) of 2022. CHIPS is aimed at bolstering U.S. manufacturing of semiconductor chips, reestablishing the United States’ leadership in semiconductor manufacturing, shoring up global supply chains, and strengthening national and economic security.

The semiconductor was invented in the U.S. At one time, we produced nearly 40 percent of the world’s chips, but U.S. production dropped to only about 10 percent of global supply. The CHIPS and Science Act aimed to change that by investing nearly $53 billion in U.S. semiconductor manufacturing, research and development, and workforce.

Washington is one of the top states for semiconductor manufacturing. Here in the Southwest Washington region, our economy has benefited for decades from the legacy presence of microchip and integrated circuit makers, the international leader in silicon wafer growing and the largest supplier of high-performance semiconductor lasers.

Senator Maria Cantwell (D-Washington), an author of the CHIPS and Science Act, reported that after just one year, there were 2,880 new high-wage semiconductor manufacturing jobs in the Pacific Northwest—including in Camas in Clark County.

In August 2024, two years after CHIPS was signed, the Biden-Harris administration celebrated historic achievements in bringing semiconductor supply chains home to the U.S. and creating family-wage jobs.

What students say about the program

Zak, a maintenance technician at SEH, said, “Clark’s program will help me go further in my career.”

Melissa previously earned a mechanical engineering degree and worked in the field for five years, but realized she wanted to make a change. “I wanted hands-on work where I would put math and theory into practice.” She said Clark’s hands-on mechatronics program has been a good fit.

Austin had taken a year of engineering classes at Clark when an advisor told him about the mechatronics program. He decided he wanted to work in manufacturing and thought mechatronics would be a better fit for him—and it has been. He said, “Clark is a good umbrella program” for graduates to step into jobs in various manufacturing industries.

Brayson was an operator at Analog Devices, Inc (ADI), a company that manufactures integrated circuits used in electronics. He said, “I was watching the technicians working and realized I wanted to expand my knowledge and become a technician.” As soon as he registered for the mechatronics program at Clark, his employer promoted him to technician.

Seth also works at ADI, and he enrolled in Clark’s mechatronics program to give him the skills he needs to be transferred to Analog’s maintenance program.

Kyle is a machinist at Sigma Design, a position he’s held for four years. He said he enrolled in the mechatronics program because “I wanted to learn how to build the systems.” With automation happening more frequently across industries, he says that earning a mechatronics degree and learning these skills will increase his job security.

Shawn, a maintenance technician diagnosed with ADHD, enrolled in the program “to grow my skills and my career.” He listed the reasons why mechatronics is a good fit for him: “The variety of the work, getting to work with my hands, troubleshooting and coming up with solutions, using my brain. And no monotony.”

After Ryker completes his Associate in Applied Technology (AAT) degree at Clark, he plans to transfer to a four-year college and earn a bachelor’s degree in mechatronics. His eventual goal is to work in aerospace, perhaps at Lockheed Martin. He said, “Clark’s program lays out the fundamentals: pneumatics, hydraulics, electrical. It’s a good basis to build on.”

Mechatronics open house

Who: Anyone interested in a career in mechatronics. High school students are encouraged to attend and explore this career option.

When: Wednesday, October 30, 5:00–7:00 p.m.

Where: Clark College Columbia Tech Center, 18700 East Mill Plain Boulevard, Room 109, Vancouver, WA

What will happen

- Learn about the mechatronics industry.

- Get a hands-on tour of the Clark College mechatronics facility.

- See equipment, meet instructors, and ask questions.

Mechatronics at Clark College

- Two-year program

- A small cohort of students that takes all classes together

- Students who complete the program receive an Associate of Applied Technology degree in Mechanical and Instrumentation Automation.

- Learn more here.

Photos: Clark College/Susan Parrish