When COVID-19 threw a monkey wrench in the program's gears, faculty got creative to keep students learning

When Clark College made the switch to online instruction during COVID-19, students showed their tenacity by adapting to new ways of learning. But some challenges take more than determination to overcome. For instance, what if your “homework” is an automobile you need to repair—what then?

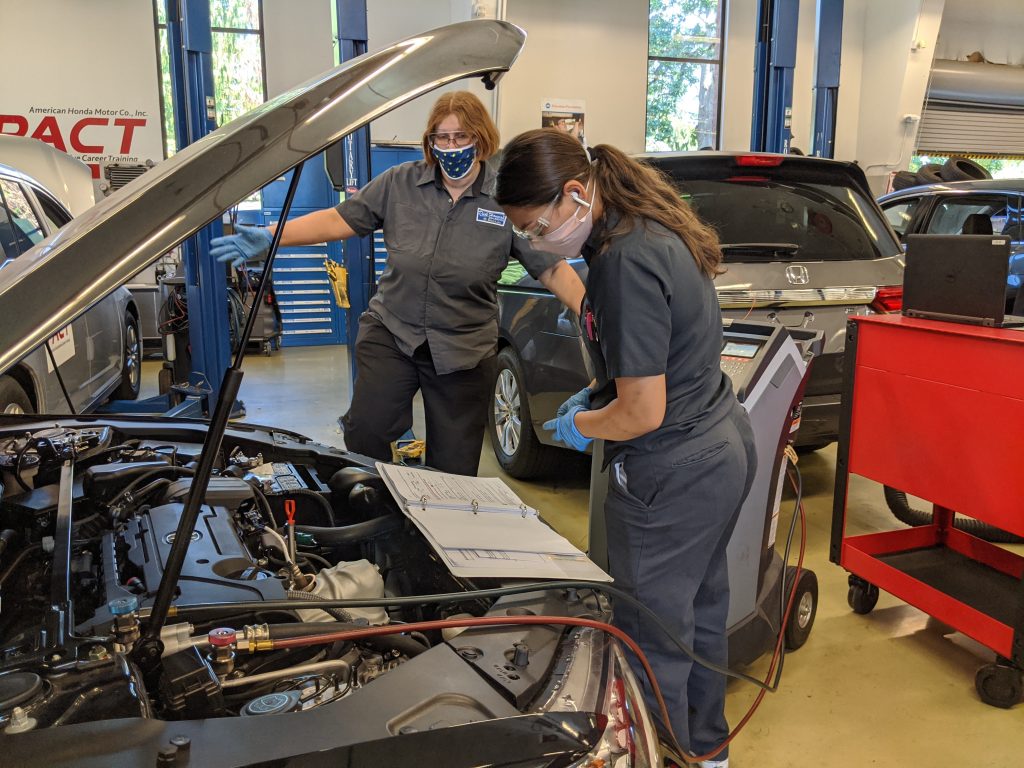

Well, that’s when your professors’ creativity and flexibility come in. When Clark’s Dealer Ready Automotive Technology programs faced COVID-19 restrictions, the college found a way to help students complete their hands-on labs in the shop.

The college set up a system for daily health screening checks. It has required face coverings for both students and employees. To comply with social distancing, the professors re-organized the garage with fewer students. The programs integrated online learning with in-person labs to keep students on the path while minimizing in-person class time. The program’s creative solutions for keeping its students learning were featured in the July edition of Northwest Automotive Trades Association (NATA) Industry Review.

Similar models will be used throughout summer and fall terms for all students taking Career Technical Education classes that require hands-on labs.

President Dr. Karin Edwards recently had the opportunity to visit Clark’s Toyota T-TEN program to talk with instructors Tonia Haney and Mike Godson and observe students working in the reconfigured, socially distanced lab environment. She learned how the automotive instructors adjusted the program to COVID-19 restrictions, helping students complete their programs while putting safety first.

Smaller classes, safer classes

Two new cohorts of students start in the Automotive Technology program each fall: T-TEN (Toyota/Lexus) and HiTECC (Honda PACT, Audi AEP and Dick Hannah dealers). Normally, each program starts with 20 students per cohort, for a total of 40.

But to maintain social distancing requirements, fewer students will be admitted in each cohort this fall.

Haney says that to begin an automotive program, a student must be hirable, have a good driving record, and be at college-level math and English.

“To diagnose with computers, you must have a good understanding of electronics,” Haney added. “But you have to be able to turn a wrench.”

Making apprenticeships work

Clark College provides hands-on instruction so graduates are equipped to step into good jobs. Clark’s automotive programs are apprenticeships that require students to concurrently be working at a dealership garage or independent repair facility so that they can put into practice what they learn in the automotive lab. Students have three days of instruction in Clark’s automotive labs weekly, followed by three days of in-dealer apprenticeship experience.

Most students work in shops in the Vancouver-Portland metro area, but students have worked at dealerships as far north as Centralia (83 miles from campus) and as far east as The Dalles (90 miles).

Although auto repair and maintenance facilities are deemed “essential services” during the coronavirus outbreak, Haney says there may be fewer apprenticeship slots available because dealers may not be hiring as many people.

Haney adds, “We may make exceptions to the apprenticeships, due to COVID.”

From a hobby to a career

Nick Ferguson, 33, lives in Tigard and has been working at Lexus of Portland for 10 years as a lube technician doing oil changes, minor maintenance and repairs. He realized that in order to advance in his career and be considered for promotions, he needed more training.

He enrolled in Clark’s Toyota T-TEN program because “I wanted to move up in the shop. It was the only way to move up.”

Ferguson earned his GED in 2005. He hadn’t attended any college classes. When he started Clark’s program two years ago, in the Lexus shop he could do work that was supervised by a team lead, but as he neared graduation from Clark’s Toyota T-TEN program, he says, “Now I’m doing anything and everything they’ll let me do.”

For the past two years, Aaron Quick, 19, has driven 140 miles round-trip between Winlock and Vancouver to participate in Clark’s Toyota T-TEN program.

“I’ve always enjoyed working on cars,” says Quick, who graduated from the program this spring. “I work on my own cars, and I work on my parents’ and friends’ cars too.”

During his senior year at Centralia High School, he started looking for a robust, hands-on automotive technology program close to home, but he couldn’t find one, so he applied to Clark and started the program immediately after high school graduation. Clark has turned Quick’s hobby into a vocation.

Haney says, “Most students starting in the fall already have been hired by a sponsoring dealer and are working throughout the summer in a variety of different positions—from lot porter to lube technicians or even line tech, depending on their skills coming in. When classes start in the fall, most students will have three months or more of experience in the dealer to relate to instruction. Even if that experience is parking cars, it still helps to relate to daily instructional topics.”

Learn more about Clark’s Automotive Technology programs at www.clark.edu/cc/auto.